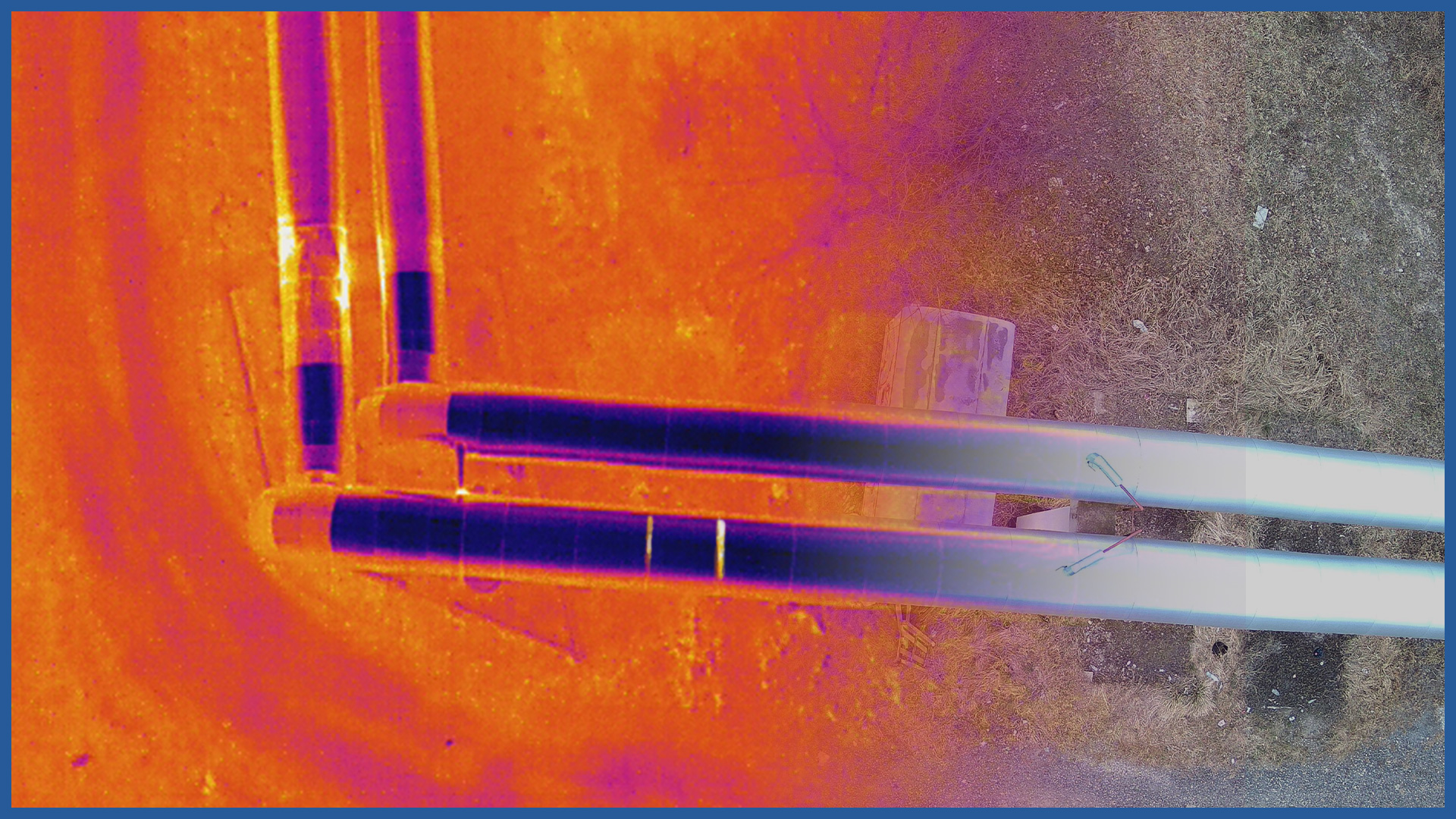

Using unmanned aerial vehicles equipped with video and thermal imaging cameras, we perform measurements and studies that allow us to carry out diagnostics of the heating network.

We detect leaks or damage to pipe sheathing invisible to the human eye, which can cause a decrease in network efficiency or failures that can even bring about interruptions in heat supply to consumers.

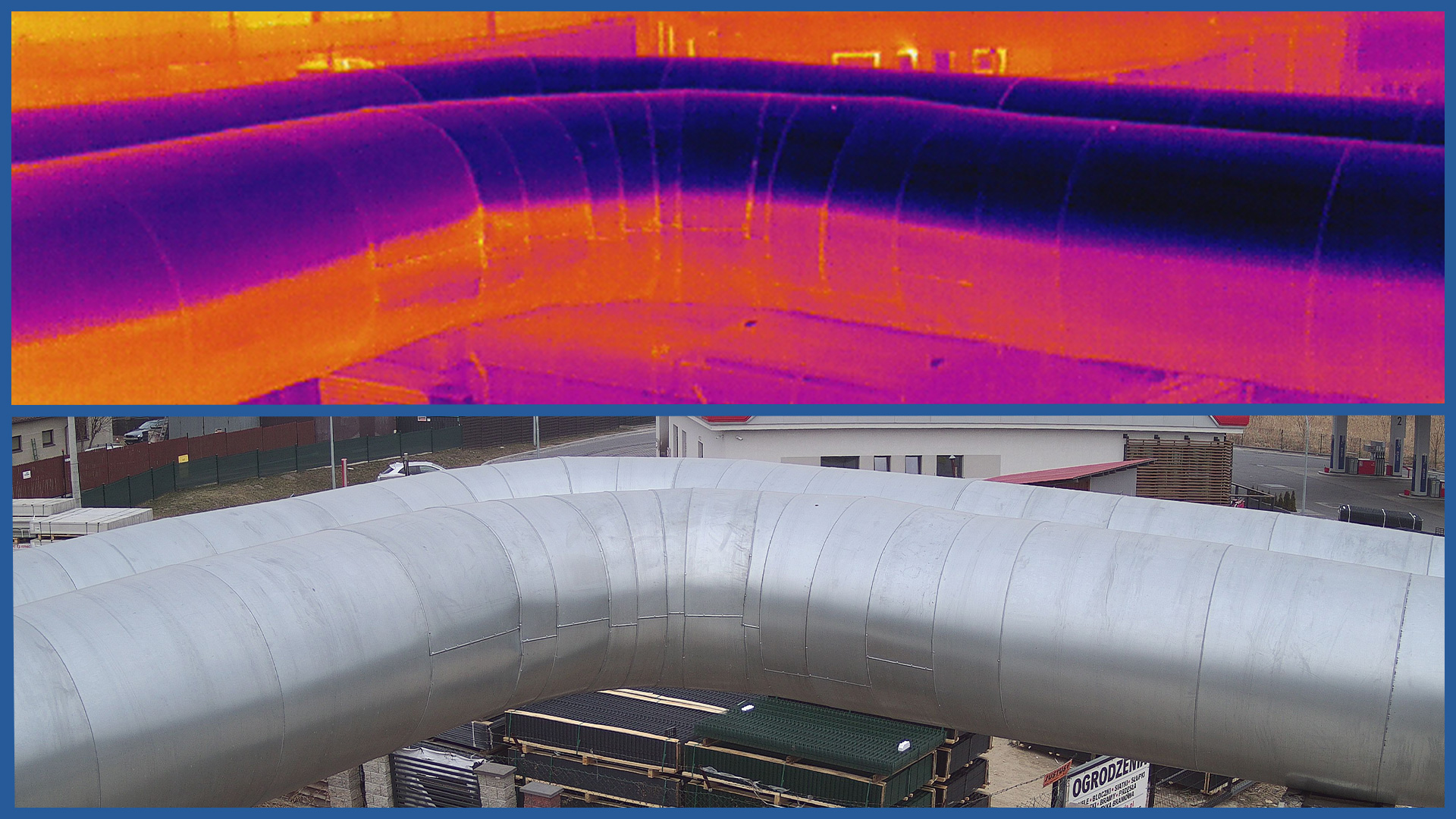

A thermal imaging camera placed on the vessel records a thermal image that allows us to distinguish places with abnormal temperature differences and thus detect probable locations of defects causing an increase in temperature of individual elements of the heating infrastructure.

The RGB camera we use, thanks to its resolution, records details of infrastructure elements in detail. The study is the basis for analyzing infrastructure elements for mechanical damage and corrosion. It also becomes a document presenting the condition of the network on a given day.

The examination of above-ground parts of heat pipelines is primarily aimed at assessing the condition of their thermal insulation and detecting various types of mechanical defects that cause heat loss. It helps and justifies the decision on possible renovation of the installation.

After completion of construction or repair work, we can prepare as-built documentation for acceptance or inspection of the completed investment.

Applications:

– supervision and maintenance of district heating networks

– modernization and renovation of existing networks.

PRODUCT CHARACTERISTICS:

| resolution | 640x512 |

| pixel size | 17 μm |

| data format | JPEG / TIFF / R-JPEG |

| sensitivity (NEdT) | <50mK@f/1.0 |

| spectral band | 7.5-13.5μm |

/ OTHER FROM HEAT NETWORKS

Airborne thermal imaging:

- qualitative analysis of the network condition

- location of the actual course of underground heat networks

Support services for network design/ supervision/ maintenance: