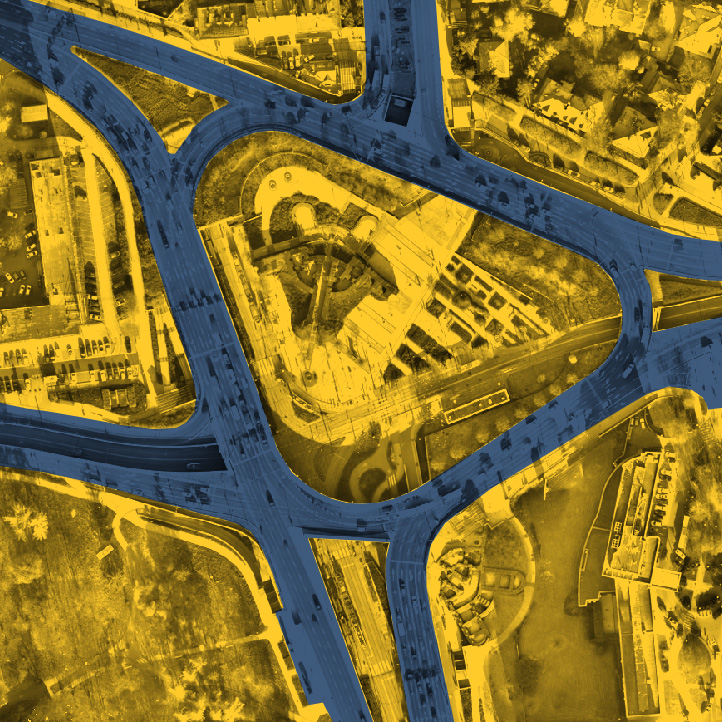

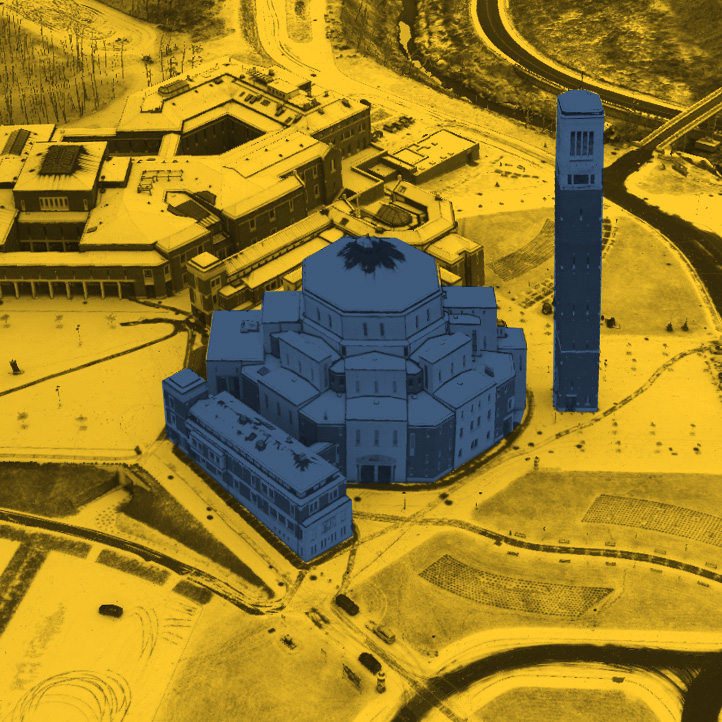

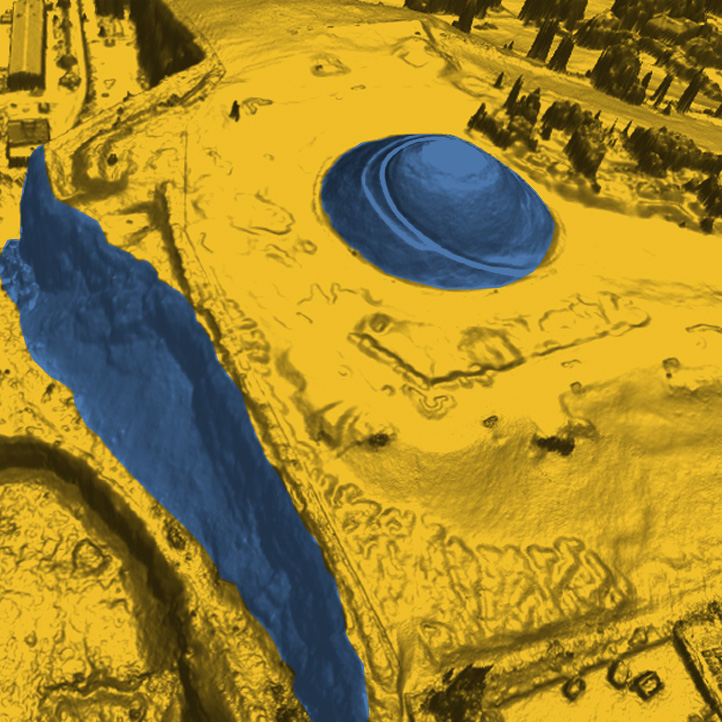

Visual inspections, as they are mainly referred to, as the name implies, involve a visual assessment of the condition of a given object. Unmanned aerial vehicles equipped with high-resolution cameras collect detailed photographic or video material on the basis of which it is possible to make appropriate analyses. Of course, visual inspections are not the only type of inspections that can be carried out with a drone. It all depends on the equipment that is mounted to it. In addition to ordinary RGB cameras, thermal imaging cameras are often used. They allow locating defects invisible to the naked eye. Read more about thermal imaging inspections in the THERMOVISION section. A laser scanner can also be used during inspections. The data obtained from it complements the material from RGB and thermal imaging cameras and makes it possible to carry out analyses in a wider range. Performing inspections using unmanned aerial vehicles primarily increases safety. During traditional methods of performing them, a worker is often exposed to potentially dangerous situations. The use of drones reduces the risk of accidents to a minimum. In addition, drones significantly reduce inspection time. Using high-end equipment, the acquisition of detailed material for analysis is incomparably shorter than in previous inspections. With a reduction in the time of performing inspections is, of course, associated with a reduction in the cost of conducting inspections. This makes it possible to carry out inspections with greater frequency. This makes it possible to detect potential problems earlier and take appropriate preventive measures more quickly. Inspections using drones provide more information than traditional inspections. The drone is often able to get into areas with difficult human access. In addition, cyclically performed inspections, provide detailed and repeatable material showing the changes taking place over time. Inspections performed by unmanned aerial vehicles are used in many fields. Among other things, they can be used to assess the condition of road surfaces or the condition of railroads. They provide valuable information about damage to engineering structures and cubic structures. They are ideal for inspections of renewable energy infrastructure. Among other things, they provide information about the condition of wind turbine blades or defects in photovoltaic panels. They also find their application in transmission infrastructure. Among other things, they allow assessment of the condition of teletechnical masts, power poles or potential collisions of overhead lines with vegetation. Inspections provide important data for industries: Inspections of above-ground infrastructure of heat network. General and detailed inspections of telecommunications masts and towers. Energetic infrastructure inspections. Inspections to evaluate the condition of railroads. Inspections of above-ground gas infrastructure.What do the inspections consist of?

Advantages of drone inspection

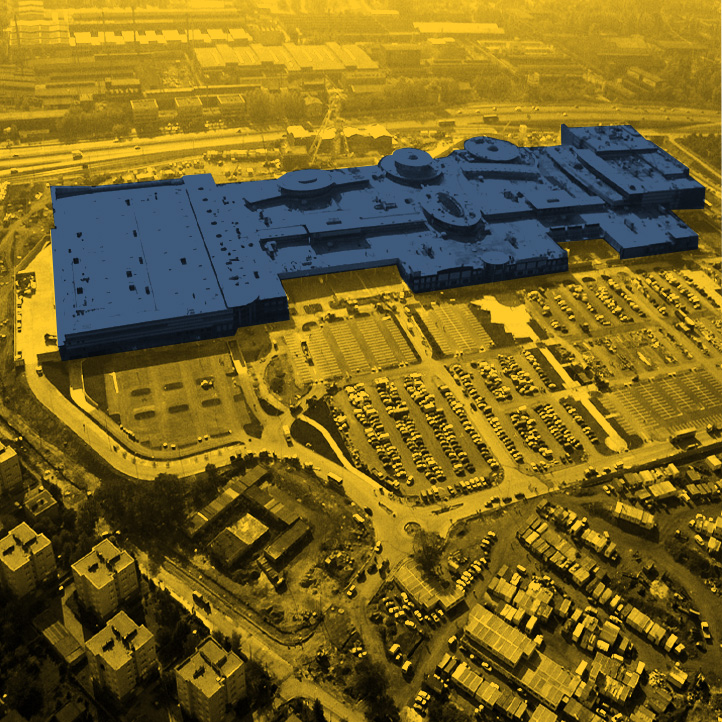

Applications

INTERACTIVE VISUALIZATION - POWERLINE - WIRES MEASUREMENT

EXAMPLES OF APPLICATIONS